Pump installation is the process of setting up and positioning a pump system to ensure its proper functioning and optimal performance. It involves several steps and considerations to ensure that the pump is installed correctly and safely. Here is a general overview of the pump installation process:

Planning and Preparation:

Determine the specific requirements of the pumping system, including flow rate, pressure, and desired performance.

Select an appropriate location for the pump, considering factors such as accessibility, stability, and proximity to the fluid source.

Ensure that all necessary permits and approvals are obtained before installation.

Equipment Inspection:

Before installation, inspect the pump and all accompanying components, such as motors, controllers, and piping, to ensure they are in good condition and free from any damage or defects.

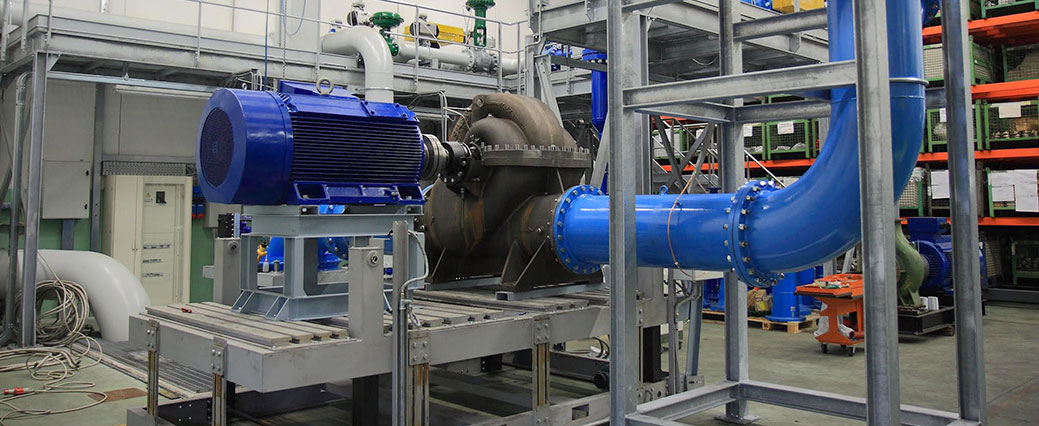

Foundation and Base:

Prepare a stable and level foundation or base to support the pump and minimize vibrations. This may involve pouring a concrete pad or using a pre-fabricated base or skid.

Alignment and Coupling:

Align the pump and motor shafts properly to ensure smooth operation and prevent excessive wear or damage. Follow the manufacturer’s guidelines for proper alignment techniques.

Connect the pump and motor using an appropriate coupling mechanism, such as flexible or rigid couplings, and ensure they are securely fastened.

Piping and Connections:

Install the necessary piping and fittings to connect the pump to the fluid source and discharge point. Use proper sealing techniques, such as gaskets or thread sealants, to prevent leaks.

Ensure that the piping is properly supported to minimize stress on the pump and maintain alignment.

Electrical Connections:

Follow electrical codes and guidelines to make electrical connections between the pump, motor, and control panel.

Ensure that all electrical connections are properly insulated, grounded, and protected from moisture or other potential hazards.

Testing and Commissioning:

After installation, conduct thorough testing to check for proper pump operation, flow rates, and pressure levels.

Verify that all safety measures, such as pressure relief valves and control systems, are functioning correctly.

Make any necessary adjustments or fine-tuning to optimize the pump’s performance.

Documentation and Maintenance:

Maintain detailed records of the pump installation, including equipment specifications, test results, and any modifications or repairs made.

Establish a regular maintenance schedule to ensure the pump is inspected, lubricated, and serviced according to the manufacturer’s recommendations.

It’s important to note that the specific installation process may vary depending on the type of pump and system requirements. Always consult the manufacturer’s guidelines and seek professional assistance if needed to ensure a successful and safe pump installation.